Dripline is proven to increase crop yield by up to 30% while also reducing water usage by as much as 50%, compared to traditional overhead irrigation methods. Because it delivers water directly to the root zone of the plant, dripline irrigation ensures that every single drop is utilised. As a result, you get healthier crops, stronger root systems, and better returns on every hectare. In short, it’s what we recommend 99% of the time.

Our main mission is to make farming more accessible for every farmer. That’s why we’re usually the ones advising farmers on how to design the most efficient and cost-effective irrigation system; one that significantly increases yield while still remaining affordable.

Moreover, the way we make our dripline reflects our dedication to quality, and just as importantly, the way we price it reflects our commitment to irrigating for a greener tomorrow.

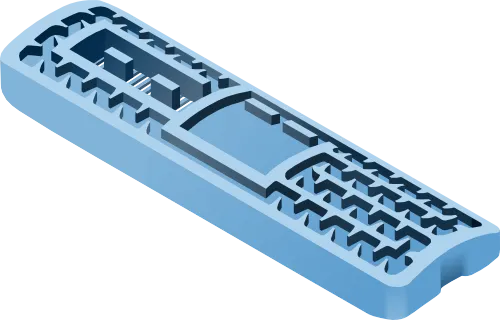

Dripline irrigation is, in essence, a pipe often referred to as flat, round, or oval, that comes in either 12 mm or 16 mm diameter. Typically, this pipe is coiled onto a roll, with emitters pre-installed or welded to the upper inner walls of the pipe. During manufacturing, holes are precisely punched over each emitter to allow for the controlled release of water at the required flow rate.

In other words, there’s no need to punch holes into the dripline pipe itself. You only need to make holes in your mainline LDPE, from where the dripline lines will run.

i.e. Dripper lines, drip tape irrigation or trickle irrigation

An irrigation method or system that delivers water directly to the root zone of the crop, in the form of single water droplets. In this system, the emitters on the inner walls determine the litres of water released per hour. As a result, the roots stay moist but never waterlogged, all while using significantly less water than other irrigation techniques.

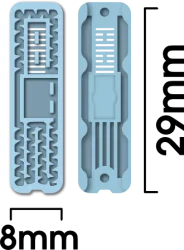

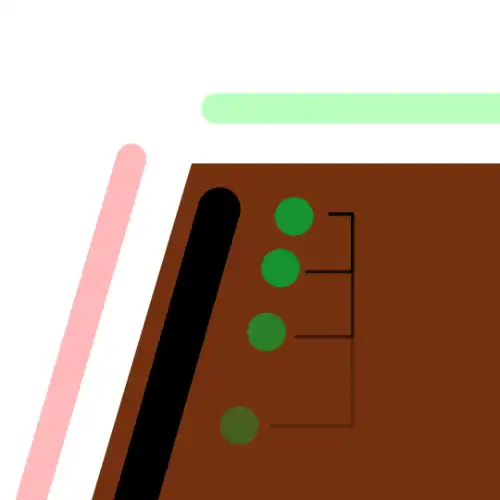

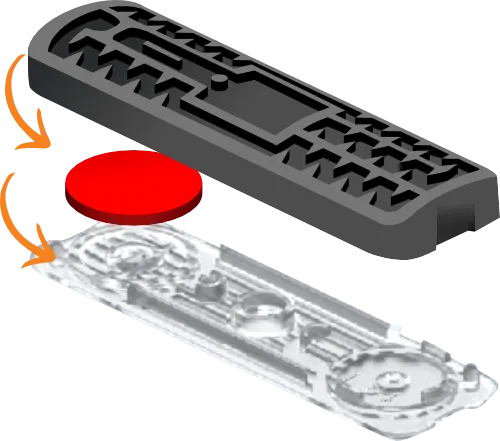

A small plastic device used to control the flow rate and litres per hour of water from the system to the emitter outlet hole. It is welded to the inner walls of the dripline pipe during manufacturing. Each emitter design is unique, carefully engineered to regulate and control the movement of water, ensuring a precise and consistent flow rate.

Also known as Non-PC Dripline

Non-Pressure Compensating (Non-PC) drip irrigation uses a turbulent-flow emitter that is specifically designed to produce the desired flow rate, as indicated on the specification label on the outside of the dripline roll, when pressure is at 1 BAR.

However, Non-PC dripline is not ideal for long laterals, underground applications, or areas with many slopes. On the other hand, it can operate effectively under gravity if the water source is positioned above the system.

PC Dripline

Pressure Compensating (PC) drip irrigation uses unique emitters that maintain a consistent water flow across all emitters in the system, even when there are pressure variations along the lines or across the field. Because of this, PC dripline is ideal for long laterals, underground applications, or areas with many slopes. Additionally, it can also operate under gravity if the water source is positioned above the system.

Known as maze dripline, labyrinthe dripline or Single-Wing Drip

Single-wing labyrinth drip irrigation tape is a type of dripline without emitters. Instead, it features a labyrinth pattern that is shaped or pressed into the side (or wing) of the tape, which helps control the water flow and acts as a channel. From there, small dripper holes are punched into the tape, allowing it to function in the same way as standard dripline irrigation, but with fewer parts required.

We only offer 0.15mm Wall Thickness, 30cm spacing, 3l/h flow labyrinth dripline.

Shortened to W/T

Refers to the thickness of the dripline walls, measured in millimetres.

Wall Thickness is simply how thick the plastic pipe’s wall is, which primarily affects the pipe’s lifespan and durability. The thicker the pipe’s walls are, the more UV is added during manufacturing, and the better it can withstand the African sun. NOTE: Have lime in your water? Get disposable drip tape!

Disposable drip or seasonal drip

Drip tape is a thin type of drip irrigation product. At Afriq Water, we manufacture drip tapes with wall thicknesses of 0.15 mm and 0.20 mm. In simple terms, all drip tape falls under the category of dripline, but not all dripline is considered drip tape.

Recommended if you have lime in your water!

An economical, durable solution

Medium dripline contains UV protection, which we incorporate directly into the material during manufacturing. This additive shields the pipe from harmful UV rays that would otherwise cause damage over time. As a result, the pipe becomes slightly stronger than drip tape, and its durability increases with higher wall thickness. Currently, we offer medium dripline in 0.30 mm, 0.40 mm, and 0.60 mm wall thickness options.

A long-term, investment solution

Durable dripline contains a high concentration of UV protection, which we blend into the material during manufacturing. This added UV shields the pipe from harmful sun exposure that would otherwise cause damage over time. Because of this, the pipe becomes exceptionally strong—almost unyielding due to its thickness. We currently offer durable dripline in 0.90 mm and 1.00 mm wall thickness options.

Outside Diameter

Refers to the measurement from one outer edge of the pipe to the opposite outer edge, expressed in millimetres.

Inside Diameter

Refers to the measurement from one inner edge of the pipe to the opposite inner edge, also expressed in millimetres.

l/h or litres per hour

Refers to the litres of water released by the emitters, typically measured per hour.

The distance between two emitters, repeated consistently along a roll of dripline. Each roll has a single, fixed emitter spacing, as different spacings cannot be combined on the same roll.

This is not a personal choice based on budget, but rather a choice made for you by the required spacing between plants of your crop type. To ensure you get the correct spacing, speak with your supplier of seeds/seedlings.

Afriq Water manufactures driplines with pre-installed emitters, meaning the emitters are welded to the inner walls of the dripline during production. They are spaced evenly apart at the specified intervals set when the order is placed.

Dripline without emitters, commonly referred to as a Blanco Pipe, meaning “blank.”

Refers to the surface area that can be irrigated by the system, depending on the design of the area.

We have ready-to-use hectare designs that include all the necessary items, fittings, and dripline rolls for two different layout options.

Before you get started, please note that these are suggested designs only. Ultimately, the most important factor to keep in mind is your maximum lateral length per line. As long as you stay within those limits, your system should perform perfectly.

Our Irrigation Designer, Justine, will be able to assist you with the items you need. Therefore, please send us a WhatsApp on +27 61 502 2547 or email us at admin@afriqwater.co.za to speak with one of our knowledgeable team members.

Before contacting us, please prepare as much info as possible regarding your field, i.e. lengths, crop requirements, etc., so that she can better assist you. In other words, the more info you give us, the better overall idea we can provide of your dripline needs.

Why: You need accurate field dimensions to plan spacing and layout. Therefore, both the length and the width are super important to ensure a complete image of the field.

What to Do: First, use a measuring wheel, tape, or GPS app (we use Google Earth to virtually help our farmers if need be) to measure the length and width of your field or growing area in meters. This way, you’ll have reliable data to base your planning on.

For example, your hectare might not be a perfect hectare, but rather a 94 m by 200 m block. That’s important to take into consideration, because every field differs and thus your needs differ. As a result, proper measurements allow you to adjust your layout to suit your exact space.

Why: Your dripline will run out from your mainline to your crops. Therefore, you need to know what the length of your mainline is to determine how many rows you’ll fit and where the fittings go.

What to Do: First, decide if the mainline will run along the top, bottom, or centre of your plot. As long as you take into consideration the max lateral line length for your type of drip, there shouldn’t be an issue. In fact, a central mainline cuts down on dripline length but needs more fittings. However, don’t just choose this blindly, rather learn more here about how to split your block up.

For example, if your field is 94 m x 200 m, choose the 200 m for your mainline. If need be, splitting up your field into smaller blocks with the use of submains is ideal, since lots of water and sufficient pressure aren’t always available. As a result, we recommend sticking under 100 m per block to be irrigated at one time.

Tip: Finally, choose the shortest length to run your dripline in, meaning that you need to choose the longer length for your mainline/submains. This way, you can get ahead of troubles caused by friction loss in your dripline.

Why: This tells you how many rows of plants you’ll be able to plant per bed. Therefore, it helps you plan your layout more efficiently.

What to Do: First, choose your crop row spacing based on info given to you by your seedling supplier. This is important because overall crop spacings are only something that they can give you, in order to ensure a good yield. As a result, following their recommendations will help you get the best growth and consistency across your field.

For example, let’s say you’re planting a larger variety of cabbage, and your seedling supplier says you need 60 cm between each row. In this case, you decide to do 2 rows per bed instead of just doing your field at 60 cm between lines, since you want to be able to easily work between the rows.

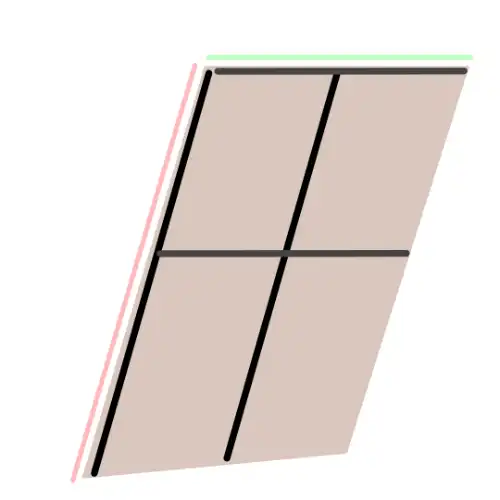

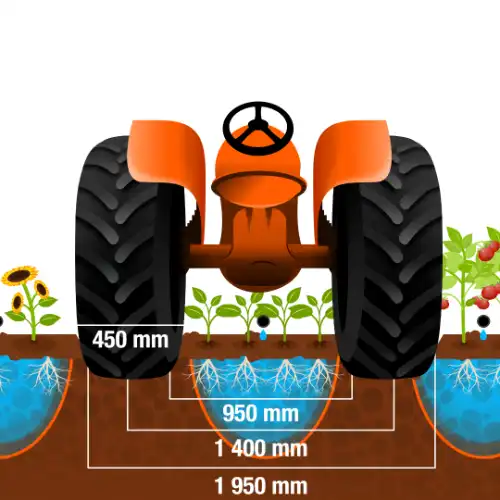

Why: If you’re going to be planting in beds or ridges, you need to be able to use a tractor in your field directly. Therefore, the layout of your beds and walkways must suit your tractor’s size.

What to Do: First, choose your walkway width based on the tractor’s tire width. This way, you’ll ensure that your tractor can move through your field easily without damaging your crops or compacting the soil in the beds.

For example, your tractor has a width of 195 cm from the outside of one wheel to the other, a width of 95 cm from the inside of one wheel to the other, and a tire width of 45 cm. As a result, your beds can only be 95 cm wide*, and your walkway is 45 cm wide**. Next, you can fit two rows of cabbages, spaced 60 cm apart between the two rows, onto your beds.***

*Your beds cannot be bigger than 95 cm because that is all that your tractor will fit between the wheels.

**Your walkway width is based on your tractor’s tire width.

***Some people multiply 2 × 60 cm here; however, that’s not necessary. In other words, all you need is 60 cm between each row of plants.

Why: To determine beds you can fit into available space. Therefore, this step helps you plan your field layout efficiently before planting.

What to Do: Simply calculate using the formula: Mainline length / (bed width + walkway width). In other words, this tells you how many full beds you can fit along your mainline.

Example:

Why: To determine amount of fittings needed (1 of each type per line). Therefore, this calculation helps you plan ahead and ensure you have all the required components before installation.

What to Do: Simply multiply the amount of beds by the number of lines per bed. In other words, this gives you the total number of drip lines you’ll need across the field.

Example:

Why: To determine dripline required. Therefore, this step helps you calculate exactly how much dripline you’ll need to cover your entire field.

What to Do: Simply multiply the amount of lines by the length of each dripline line. In other words, this gives you the total length of dripline required.

Example: in step 2, we chose the longer of the two sides of the field for our mainline. This means that the shorter section (the 94 m) is where our dripline will run.

Click on ‘Customise’ for our variety of dripline customisations available. Keep in mind:

Why: Do your research on the options available before you start, so that you can avoid disappointment when your chosen drip doesn’t perform as expected. Therefore, taking time to compare options will help you choose the most suitable product for your needs.

Take into consideration:

Why: A sufficient filter is essential in extending your drip’s lifetime. Therefore, choosing the correct one from the start helps prevent clogging and system failure. Learn more here.

What to Do: First, multiply Emitters in meters x Total meters of dripline (not just what you’re using right now) x Flow Rate = Round Up. In other words, this gives you the total flow your filter needs to handle.

Example: For example, let’s say you choose a 120 cm spacing between emitters, you choose a 0.30 mm economic medium dripline wall thickness, and you choose 2 l/h flow because that gives you a max lateral length of 220 meters per line. As a result, with those specs, you’ll need to order 22 rolls of 1 250 m (the standard for this roll spec).

In conclusion, you will need a filter that can handle at least 46 m³/hr. Therefore, we advise sizing up. In this case, our Single Plastic Filter with a Stainless Steel clamp 63 mm inlet/outlet would work best, as it has a flow capacity of 48 m³/hr. Finally, learn more about choosing between disc and screen filters here.

To begin with, only Non-PC Emitters are available.

Additionally, they are available in 0.40mm, 0.60mm and 0.90mm Wall Thicknesses.

They are also available in 0.8, 1.3, 1.6, 2, and 3.8 l/h flow rates.

Finally, they are available in 20, 30, 40, 60, 75, and 90cm spacing.

In contrast, both Non-PC and PC Emitters are available.

Non-PC are available in 0.15mm, 0.20mm, 0.30mm, 0.40mm, 0.60mm, 0.90mm, and 1.00mm Wall Thicknesses.

Meanwhile, PC are available in 0.40mm, 0.60mm, 0.90mm, and 1.00mm Wall Thicknesses.

Furthermore, Non-PC are available in 0.8, 1.3, 1.6, 2, and 3.8 l/h flow rates.

PC Emitters, on the other hand, are available in three different types; i.e. Anti-Syphon, Drain and Non-Drain*. Flow Rates for PC are available in 1, 1.5, 2, 2.4, and 3.8 l/h**.

In terms of spacing, Non-PC are available in Blanco***, 20****, 30, 40, 50, 60, 75, 90, 100, and 120 cm spacing.

Similarly, PC are available in 20****, 30, 40, 50, 60, 75, 90, 100, and 120 cm spacing.

*Non-Drain Emitters are only available upon request, with longer lead times.

**2.4 and 3.8 l/h PC Emitters are only available upon request, with longer lead times.

***Blanco dripline only available in Non-PC, for 0.90mm and 1.00mm Drip.

****20cm Spacing not available for PC 0.40mm and 0.60mm W/T.

When choosing an ideal wall thickness, consider the following:

Firstly, the longer dripline lasts, the more it will cost per metre. Therefore, farmers need to consider their budget across the range available.

Secondly, as dripline pipes get thicker, their friction loss increases. Consequently, you should consider the maximum lateral length of each drip type. Learn more.

Finally, seasonal drip tape is always ideal for water with lime, since the lime will clog the delicate emitter beyond repair, even if the pipe lasts years to come. However, thicker, heavier dripline will last much longer under ideal circumstances.

2 500 m

3 Months

Paper-thin drip tape, with plastic lending it some strength. If you have ANY lime in your water, this is the drip tape for you. Investing in a five-year drip if lime will kill your dripline emitters in 3 months does not make economic sense.

2 000 m

6 Months

Paper thin drip tape, with plastic lending it some strength. A slightly more durable economic choice. Contains some UV for a slightly longer lifespan.

1 250 m

1 Year

Soft yet slightly firm, bendable dripline. An economical yet more durable choice, with more UV making it slightly thicker.

1 000 m

2 Years

Also available in 12 mm pipe dia. & Pressure Compensating**

Firm, yet flexible dripline. A good economic choice that will last for longer than tape, ideal for farmers who need to consider their economic situation to decide what will work best.

700 m

4 Years

Also available in 12 mm pipe dia. & Pressure Compensating**

Thick, yet bendable dripline. Contains more UV than the 0.40 mm, making it thicker and with a longer life expectancy, making it a long-term solution.

500 m

5 Years

Also available in 12 mm pipe dia. & Pressure Compensating**

Very thick, slightly unyielding and strong. High UV%, a very popular long-term solution.

400 m

5 Years +

Also available in Pressure Compensating**

Most durable dripline. Extremely thick, unyielding and strong. With high UV%, this dripline is the long-term solution.

*Lifetime estimates are for the dripline pipes only, as any particles (lime, dirt, sand, etc.) will clog emitters.

**Pressure Compensating Options below.

Before choosing the ideal emitter spacing on a roll, consider the following:

Firstly, your plant spacing almost always determines your emitter spacing. Therefore, this spacing should be supplied to you by your seedling or seed supplier. Learn more.

Secondly, consider the maximum lateral length of each flow rate in combination with the wall thickness and emitter spacing. As a result, you’ll be able to choose the most efficient setup for your specific field layout. Learn more.

Carefully choose your the ideal emitter flow rate, consider the following:

Firstly, different types of soil hold onto water differently; i.e. clay soil does not drain, whereas loamy soil does. Therefore, understanding your soil type is essential to selecting the right flow rate.

Secondly, consider how much water the crop actually needs. For example, if 2 litres an hour (our most popular choice) is too much water per session, watering times can easily be customised to the needs of the farmer. Learn more about how to calculate your water application.

Finally, every type of flow rate affects the pipe’s friction loss. As a result, it’s important to consider the maximum lateral length of each flow rate in combination with the wall thickness. Learn more.

Pressure Compensating is ideal for:

Non-Pressure Compensating is ideal for:

Accurate flow at 1 BAR. Ideal for shorter, flat areas and lengths

🌢 Advanced water inlet design with industry-leading filtration area that prevents particle insertion

🌢 The large cross-section, along with the high turbulent flow path, provides some clogging resistance

Accurate flow at different BARs pressure. Ideal for longer, sloped fields and lengths

🌢 Advanced labyrinth with wide water passages

🌢 The large cross section along with the high turbulent flow path, provides high clogging resistance

🌢 Chemical resistant silicone diaphragm

🌢 Laser-welded plastic cover to ensure sufficient and accurate flow

In most cases – NO. You can do it either on your own, with a few friends, or hire helping hands. Installation is easy enough that it does not require a lot of technical expertise.

Afriq Water manufactures not only dripline, but dripline fittings, too! Our drip fittings are available in a full 16mm range, as well as some 12mm fittings. If you need anything for your in-field dripline system, then you know what name to look for in your local shop!

Use with 0.15 mm and 0.20 mm Wall Thickness

disposable drip tape

Use with 0.30 mm, 0.40 mm and 0.60 mm Wall Thickness medium dripline

Use with 0.90 mm and 1.00 mm Wall Thickness heavy / durable dripline

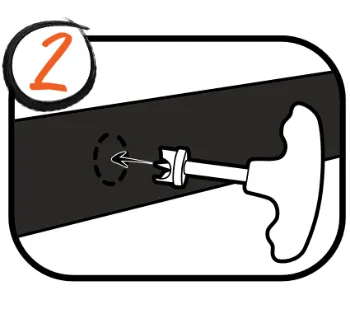

Manually punches a 18 mm hole into the LDPE mainline. The tool is easy to use, but very sharp, so beware. Afterwards, you can push your grooved sealing rubbers into the hole created.

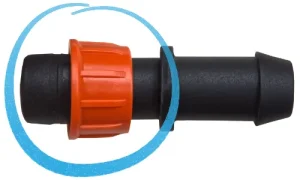

Pushed into the hole that was created using the Perforation Tool, to prevent leaks, with an opening of 16 mm. Always purchase equal amounts of Rubbers and Off-Take Connectors. Use with minimum 40 mm LDPE.

Pushed into the hole that was created using the Perforation Tool, to seal incorrectly punched holes/old holes. Use with minimum 40 mm LDPE.

We also recommend grabbing some of these with main orders, as there are generally small mishaps when cutting uneven holes when just starting out.

Connects dripline and mainline pipes. Inserted into the Sealing Rubber, with dripline pushed into place over the fitting. Also available as Mini Valves, which differ from normal off-takes in that they allow you to control the flow for every line it’s connected to, instead of relying on mainline valves.

Used in places where controlling flow by opening/closing water to a line drip is desired. Some Mini Valves are Off-Take Connectors (for an entire line), others are fittings (for sections of a line).

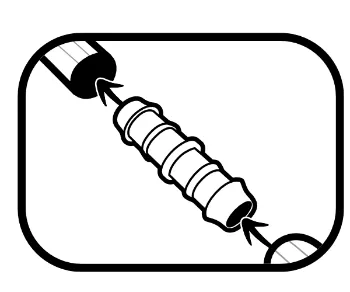

Used to join two pieces of dripline that have been cut/damaged. Dripline is pushed over both sides of the fitting and fastened.

Used to end a line of dripline tightly for a leak-free seal. Dripline is pushed over the fitting and fastened.

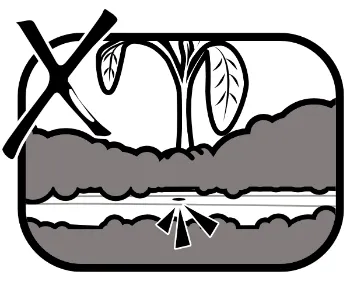

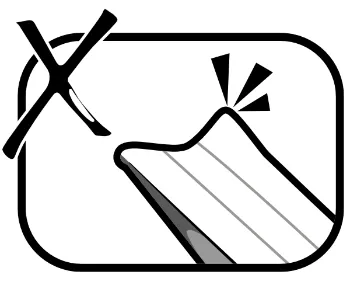

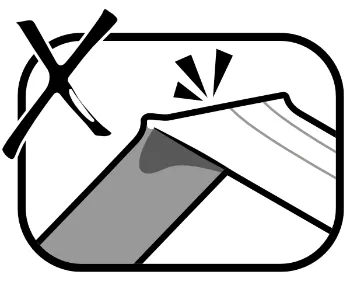

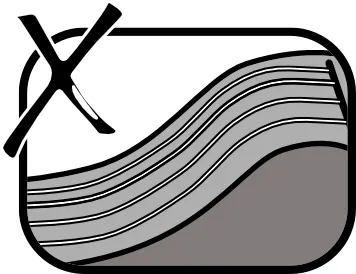

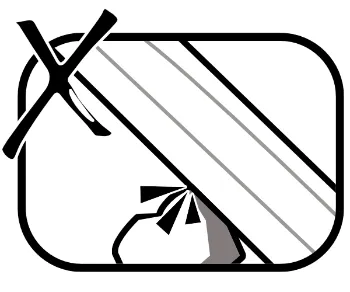

Do not bury dripline

As this will lead to blocked emitters

Do not bend dripline

As this will lead to breakages

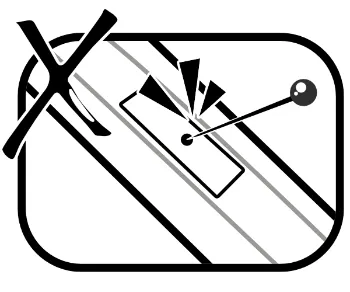

Do not cut dripline

Without fittings to fix dripline line

Firstly, before anything else – add sufficient 130 micron filters

after water source and before every block

Firstly, before anything else – add sufficient 130 micron filters

after water source and before every block

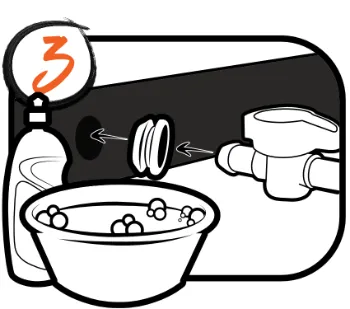

Install mainline and punch holes

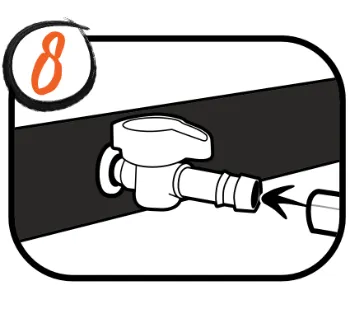

Insert sealing rubbers & Off-Take Connectors

Tip: Use warm, soapy water to help this process

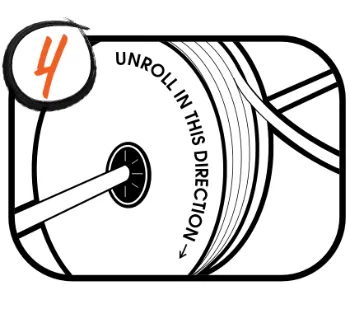

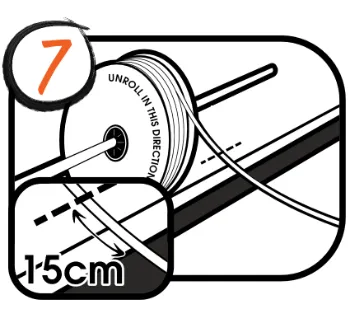

Unroll dripline on spool

Down the bed/ridge

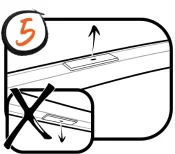

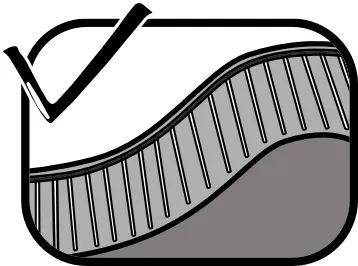

Ensure drippers are facing up

To avoid blockages

Anchor the dripline at the end of the line

With a stick through the end plug.

This suggestion is directly from the mouth of farmers, who, conversely, have told us that dripline sometimes blows in heavy winds. Agricultural hooks are even better.

Cut dripline line 15cm above mainline

To leave enough space for expansion/contraction of drip line

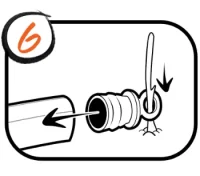

Connect dripline line to mainline fittings

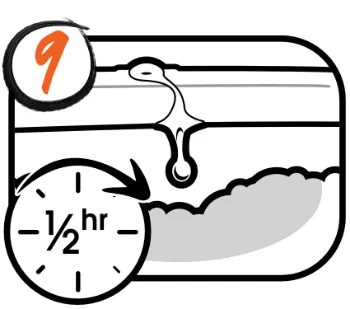

Test dripline for 30 minutes

To wet ground and look for damage

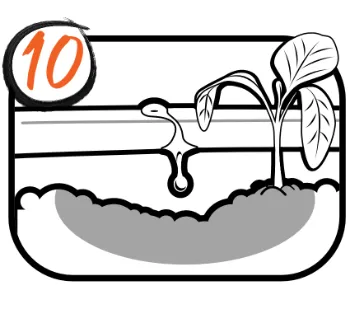

Plant seedlings

Next to drippers,

Mulch with hay, bark or plastic

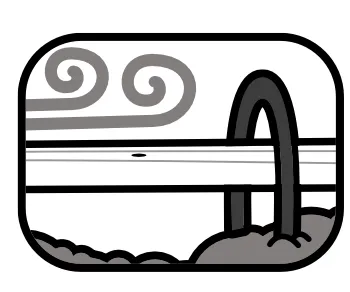

Keep water source above system

If a slope is present

Install dripline horizontally across contours

To assist with flow

Remove rocks under drip

To prevent holes and breakages

Repair dripline with couplings

To prolong the use you get our of dripline

Anchor down dripline in windy areas

To keep dripline lines straight

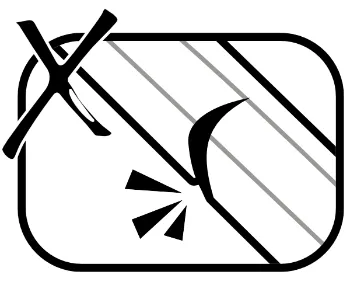

Do not unclog emitters with a needle

As the system is incredibly delicate and will get damaged

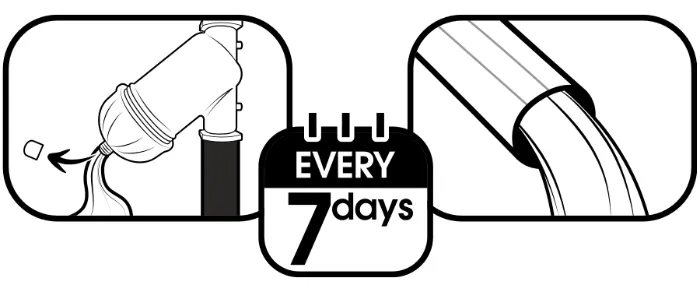

Every 7 days, you should flush and clean your filter & flush your dripline lines

To get rid of pollutants & build-up of algea

We would love to help you find your nearest retailer and get you started on your irrigation journey.

You can contact us to find your nearest retailer +27 61 502 2547

Or you can contact our distributor, Irrigation Unlimited, when we’re unable to assist: PTA +27 12 736 2121 | CPT +27 21 946 1194

That sounds like a plan! We recommend contacting our distributor, Irrigation Unlimited, to find out how you can register with them.

The benefits of buying and reselling through them is massive. They have an incredibly wide range of irrigation materials available, their transport options are unbeatable, and their service is top-class.

Please contact them directly to find out more here.

Non-PC dripline is ideal for most uses, but PC is worth the investment for specific situations.

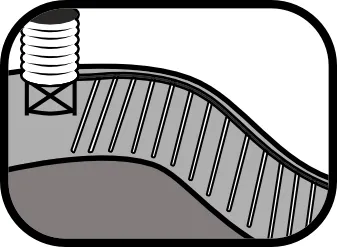

PC or Pressure Compensating Dripline is ideal for long laterals because:

Normal dripline designs require your block to be split into smaller zones due to the maximum lateral length limits.

For example:

With PC dripline, you can extend your lateral lengths without compromising uniformity, helping you avoid these extra costs.

PC or Pressure Compensating Dripline is ideal for anti-clogging because:

Our PC emitters are designed by some very clever engineers — they’ve fine-tuned the technology to include self-flushing and anti-clogging features. These enhancements make PC dripline more resilient in real-world conditions, where particles and pressure changes can mess with standard emitters. Learn more here.

PC or Pressure Compensating Dripline is ideal for sloped fields because:

Non-PC dripline struggles to deliver even pressure on slopes. Water naturally flows downhill faster, meaning lower parts of your field receive more water, and higher parts get less.

PC emitters solve this with smart mechanics:

A thin plastic layer regulates entry.

A silicone diaphragm expands and contracts with pressure to ensure that each emitter delivers the same amount, no matter the elevation.

*NOTE: This 78 m figure is just one example. Lower emitter flow rates (e.g. 0.8 l/h or 1.3 l/h) allow for longer laterals. So, the final decision depends on your flow rate, pipe diameter, and spacing — there’s more than one way to solve a design challenge. Learn more here.

Afriq Drip comes in two main diameters – 12mm and 16mm.

Why you should use 16mm instead of 12mm:

16mm Fittings are by far the most widely available dripline fittings on the market. If you don’t have time to source our fittings, most Co-Ops or irrigation shops do keep stock of 16mm drip fittings. This is not at all the case with 12mm, as 12mm dripline isn’t as common and most places don’t keep stock. We manufacture 12mm fittings, but even here we don’t keep stock as it is so rarely used.

Another reason is that your max lateral line length for the 16mm is longer than the 12mm line length.

For example:

A 16mm Pipe Diameter at 0.90mm Wall Thickness pipe, with 60 cm spacing between emitters, at 3.8 l/h, has a max lateral line length of 80m.*

The same dripline specifications at 12mm has a max lateral line length of 64m*.

Why you should use 12mm instead of 16mm:

Retailers and farmers can enjoy the fact that 12mm comes in a smaller roll and therefore has a cheaper transport cost per roll than 16mm.

What we recommend

16mm Diameter dripline. Always. We recommend this for most applications.

*Subject to a 0% slope and a 10% flow variation.

You can find more info on our Wall Thickness options under ‘Customisations’ in the section above. But in short, the thicker the Wall Thickness, the longer the pipe will last.

The following lifetimes are for outdoor use, in ideal conditions (a sufficient filter, no lime in water*, excluding damage from pests):

*NOTE: This does come with an exception; if you have lime in your water, it will clog the emitter that controls the water flow beyond repair, making the whole system unusable – go with a disposable drip tape (0.15mm or 0.20mm) in this case.

Afriq Drip manufactures a range of dripline options with emitter spacing from 20 cm to 120 cm.* But how do you choose the right spacing for your field?

Here are a couple of key questions to ask:

What crop are you planting / what does your seedling supplier recommend?

The golden rule of dripline is simple: there should be an emitter next to each plant.

For example:

Pumpkins are usually spaced 75–100 cm apart.

Spinach is commonly spaced 20–30 cm apart.

This means your emitter spacing should match the plant spacing recommended by your seedling supplier or based on your crop plan.

What if you’re planting different crops with different spacings?

That’s where dripline shines. Unlike overhead sprinklers, dripline doesn’t just wet the surface or top 5 cm of soil — it creates a subsurface water “bubble” that spreads laterally through the soil.

The exact shape and spread of that bubble depends on your soil type and how long the system runs, but the benefit is that the water can reach across multiple root zones, even if plants aren’t spaced exactly at each emitter.

So if you’re planting a variety of crops, choosing an average emitter spacing (e.g. 30 cm) can work — though it’s not always the perfect fit for every crop. It’s a practical solution when you need to balance flexibility with efficiency.

*Note: Emitter spacing availability depends on wall thickness and pipe type.

Learn more here.

Afriq Drip offers emitters in a range of flow rates, from 0.8 l/h to 3.8 l/h, depending on the pipe diameter and the drip type (PC or Non-PC).

Here are the two key questions you need to ask when choosing your dripline flow rate:

How much water do you have available to irrigate your block at a time?

Your pump, tank, or borehole can only deliver a certain flow rate (litres per hour). The higher the flow rate of each emitter, the more water your system needs at once.

For example:

A 0.8 l/h emitter uses less water per hour than a 2 l/h emitter — but you’ll need to run it for longer to give your plants enough.

A 2 l/h emitter waters faster, but if you have limited water supply, you might run out of pressure or water before the whole block is covered.

Choose a lower flow rate if your water supply is limited or if you’re running multiple blocks on a tight schedule.

What’s the maximum lateral length you can run before friction loss becomes a problem?

As water flows through your dripline, it loses pressure due to friction, especially over long distances. The higher your emitter’s flow rate, the shorter your maximum lateral line can be.

For example:

A 16mm Pipe Diameter at 0.20mm Wall Thickness pipe, with 40 cm spacing between emitters, at 3.8 l/h, has a max lateral line length of 69m.*

Drop that flow rate to 1.3 l/h, and suddenly your dripline has a max lateral line length of 144m*, because the friction loss is less.

Lower flow rates = longer runs, but slower watering.

Higher flow rates = shorter runs, but faster delivery.

Learn more here.

No need! Our dripline comes with emitters pre-installed onto the inner wall of the pipe, with a punch accurately placed on the emitter, to allow for water flow, at whatever cm spacing between emitters you choose when ordering from your supplier.

We can help you to determine your items required so that you can start shopping around. We do need the following before we can help you:

We cannot help you with pump specs unfortunately, but we can assist you with determining your system’s flow to ensure that your pump is sufficient. Learn more about how to do that here.

Note: For most installations of blocks, a normal swimming pool pump is sufficient, since the pressure required is quite low.

Still Have Questions? We’re Here to Help! Contact Us

Belinda Hall

As you know, in the karoo every single drop of water counts and you absolutely have to make it count. Their drip line made everything so easy and effective.

Manual

Koketso, Bamalatswe

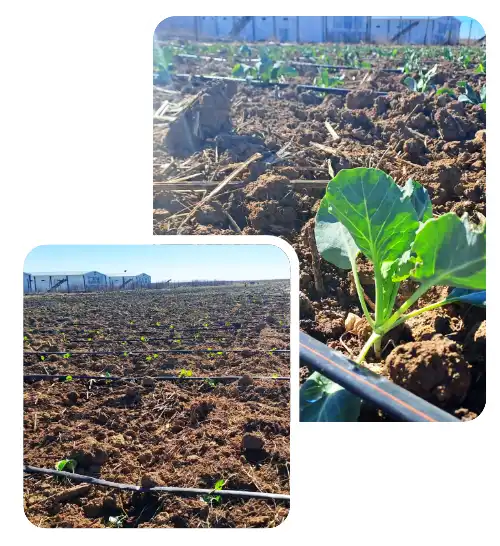

Green Farm

Our drips irrigation are so perfect 👌🏾

Cabbage Farmer

Drip + Quick Coupling making MAGIC!👆🏿

Anonymous

Great product. Great people👏🏽

Steve

Hennelien

Loving it! 💃🏻